Job costing in construction can be a complex and challenging process. At Adding Technology, we’ve seen firsthand how accurate job costing can make or break a project’s profitability.

In this post, we’ll explore common job costing examples and solutions that construction companies face daily. From time tracking issues to material cost fluctuations, we’ll provide practical strategies to overcome these hurdles and improve your bottom line.

Construction job costing presents numerous challenges that can significantly impact project profitability. We’ve identified four major hurdles that consistently plague construction companies: time tracking inaccuracies, volatile material costs, overhead allocation complexities, and change order mismanagement.

Time tracking forms the backbone of accurate job costing, yet it often contains errors. Manual timesheets prove prone to mistakes, whether through honest forgetfulness or deliberate time padding. According to the American Payroll Association, businesses lose up to 7% of their gross annual payroll to time theft. This translates to thousands of dollars in misallocated labor costs for even small construction projects.

The construction industry faces particular vulnerability to material cost fluctuations. In 2022, the Associated General Contractors of America reported that bid prices were climbing at a 19.8% year-over-year rate by June. This volatility makes it challenging to estimate project costs accurately and maintain profit margins. Without real-time tracking and adjustment mechanisms, contractors risk significant financial losses due to unexpected price hikes.

Distributing overhead costs fairly across multiple projects remains a persistent challenge. Many construction companies still rely on outdated methods (like applying a flat percentage to direct costs). This approach often leads to over or under-allocation, distorting project profitability. A survey by the Construction Financial Management Association revealed that 62% of contractors struggle with accurate overhead allocation, impacting their ability to price jobs competitively and maintain profitability.

Change orders occur commonly in construction, but they often become a source of financial strain and disputes. The Navigant Construction Forum found that the average processing time for change orders is 67 days, during which costs can escalate and work may proceed without proper documentation. This delay in processing and approval can lead to cash flow issues and disputes over payment, further complicating the job costing process.

These challenges require a strategic approach combining technology, process improvements, and industry best practices. In the next section, we’ll explore effective solutions to these common job costing hurdles (including digital time tracking systems and real-time material cost monitoring), helping construction companies achieve greater accuracy and profitability in their projects.

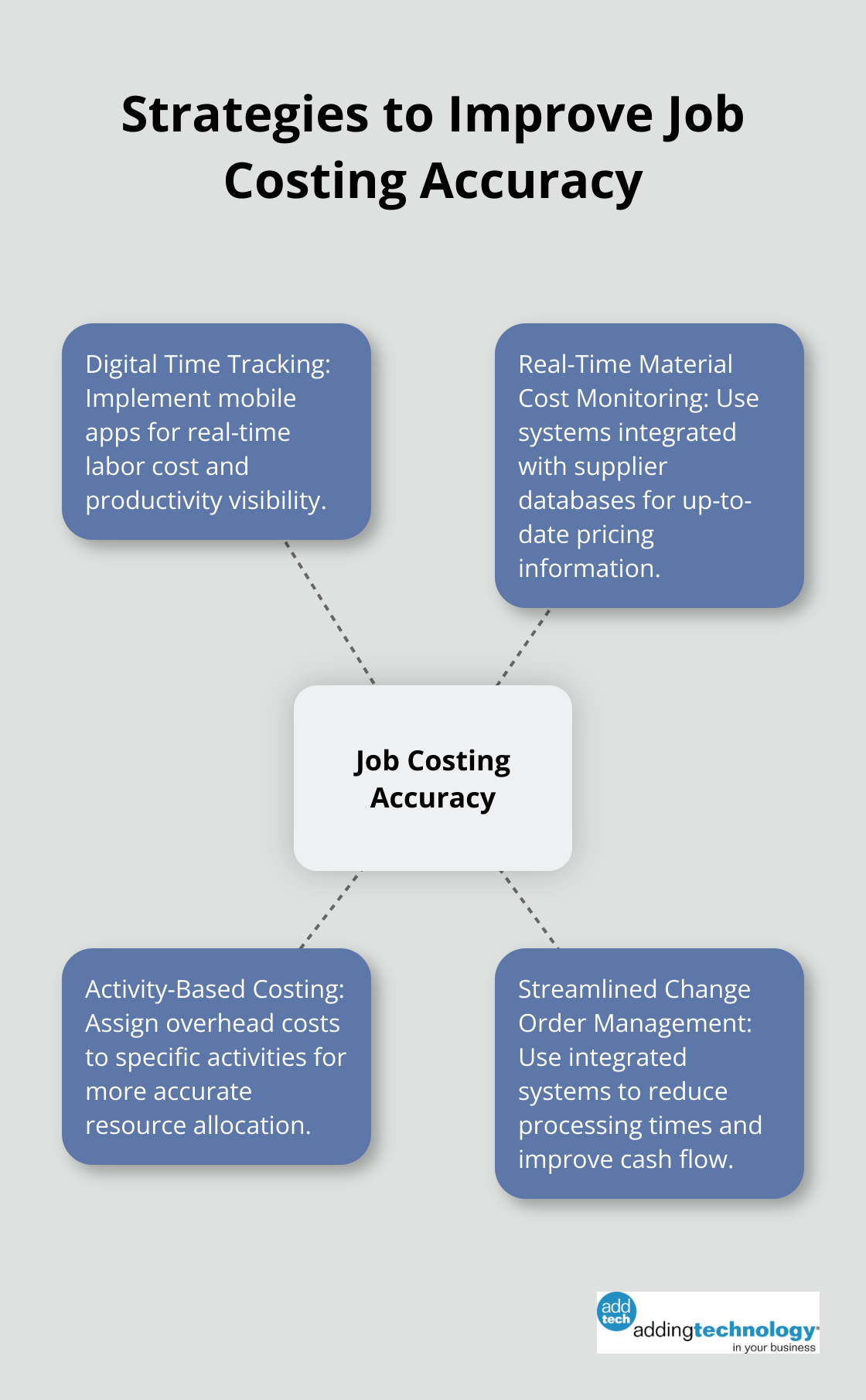

At Adding Technology, we’ve identified several effective strategies to tackle common job costing challenges in the construction industry. These solutions can significantly enhance financial accuracy and project profitability.

The construction industry moves away from paper-based systems. Digital time tracking solutions offer real-time visibility into labor costs and productivity. Mobile apps allow workers to clock in and out on-site, automatically capturing GPS location and job codes. This level of detail improves accuracy and provides valuable insights for future project estimates.

With rapidly fluctuating material costs, static estimates quickly become obsolete. Real-time material cost monitoring systems integrate with supplier databases to provide up-to-the-minute pricing information. This allows project managers to adjust budgets and make informed purchasing decisions on the fly.

A mid-sized commercial contractor implemented a real-time material cost monitoring system and saw a 4% reduction in overall material costs within the first year. They capitalized on price dips and avoided unexpected cost increases by timing their purchases strategically.

Traditional methods of overhead allocation often fail to accurately reflect the true cost of specific activities. Activity-based costing (ABC) provides a more nuanced approach by assigning overhead costs to the activities that drive them.

Instead of applying a flat percentage for equipment costs, ABC might allocate based on actual machine hours used on each project. This level of detail allows for more accurate pricing and helps identify inefficiencies in resource utilization.

Efficient change order management maintains project profitability. Integrated change order systems that connect field operations with the back office can dramatically reduce processing times and improve cash flow.

These systems allow for real-time submission of change orders from the field, automated approval workflows, and immediate budget updates. This level of integration ensures that all project stakeholders have visibility into potential cost impacts, reducing disputes and delays.

These solutions significantly enhance job costing accuracy, leading to more competitive bidding and improved project profitability. But how do these strategies play out in real-world scenarios? Let’s explore some concrete examples in our next section on successful job costing implementations.

A mid-size residential builder in Texas overcame cost overruns and inaccurate estimates. They implemented a comprehensive digital time tracking system and real-time material cost monitoring. The results proved impressive:

The key to their success? Integration of job costing data across all departments (from estimating to purchasing to field operations). This holistic approach allowed for more accurate bidding and tighter cost control throughout the project lifecycle.

A commercial contractor in California faced challenges with project visibility and overhead allocation. They adopted an activity-based costing system and implemented advanced project management software. The outcomes transformed their operations:

The contractor now has a clear view of costs at every project stage, which allows for proactive decision-making and improved resource allocation. This level of visibility has become a competitive advantage in a tight market.

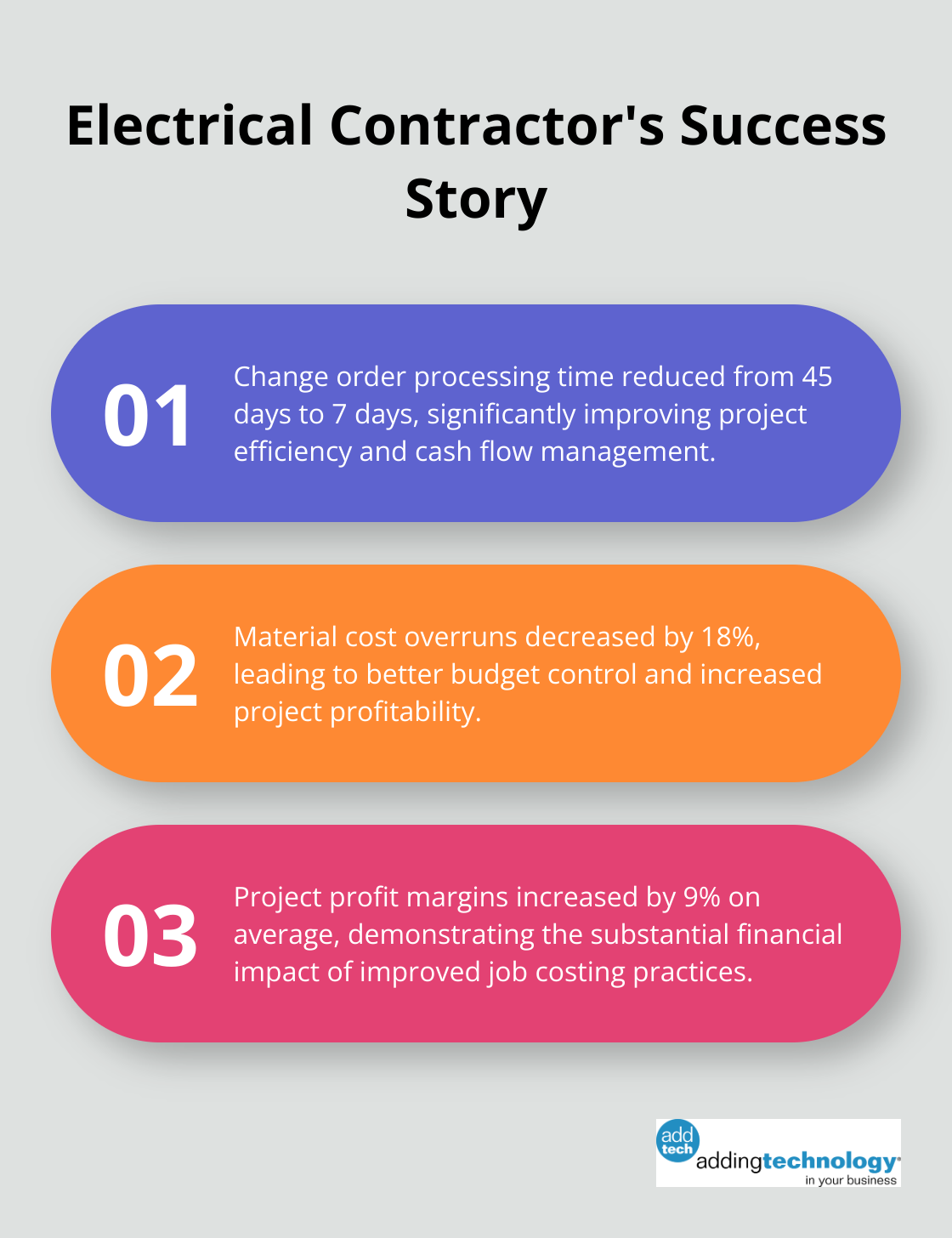

An electrical contractor in New York grappled with frequent cost overruns, particularly due to change orders and material price fluctuations. They implemented an integrated change order management system and real-time cost tracking. The impact proved significant:

These case studies demonstrate the tangible benefits of modernizing job costing practices. While each company faced unique challenges, they all saw substantial improvements in profitability and operational efficiency.

For construction businesses looking to achieve similar results, partnering with experts like Adding Technology can provide the guidance and tools needed to revolutionize job costing practices. Our tailored solutions and industry expertise can help you navigate the complexities of financial management in construction, which allows you to focus on what you do best – building great projects.

By implementing cutting-edge technology, construction companies can gain real-time job costing and financial insights necessary for informed decision-making and improved profitability.

Job costing in construction presents significant challenges, but effective strategies and tools can overcome these hurdles. We explored various job costing examples and solutions that demonstrate how technology and process improvements transform financial management in the construction industry. From digital time tracking to real-time cost monitoring, these solutions address common pain points and drive project success.

Accurate job costing enables informed decisions that fuel business growth. Construction companies that adopt modern job costing practices gain a competitive edge in the rapidly evolving industry. They can bid more accurately, allocate resources efficiently, and respond quickly to market changes or project scope adjustments.

Adding Technology specializes in helping construction companies revolutionize their job costing and financial management processes. Our expertise in integrating cutting-edge technology with industry best practices can help you build a solid financial foundation for your business (while you focus on delivering exceptional construction projects). Don’t let outdated methods hold your business back – embrace the power of modern financial management today.

At adding technology, we know you want to focus on what you do best as a contractor. In order to do that, you need a proactive back office crew who has financial expertise in your industry.

The problem is that managing and understanding key financial compliance details for your business is a distraction when you want to spend your time focused on building your business (and our collective future).

We understand that there is an art to what contractors do, and financial worries can disrupt the creative process and quality of work. We know that many contractors struggle with messy books, lack of realtime financial visibility, and the stress of compliance issues. These challenges can lead to frustration, overwhelm, and fear that distracts from their core business.

That's where we come in. We're not just accountants; we're part of your crew. We renovate your books, implement cutting-edge technology, and provide you with the real-time job costing and financial insights you need to make informed decisions. Our services are designed to give you peace of mind, allowing you to focus on what you do best - creating and building.

Here’s how we do it:

Schedule a conversation today, and in the meantime, download the Contractor’s Blueprint for Financial Success: A Step by-Step Guide to Maximizing Profits in Construction.” So you can stop worrying about accounting, technology, and compliance details and be free to hammer out success in the field.